Businesses specializing in system integration, R&D technology, and innovation face unique challenges - especially when it comes to government contracts and data security.

When dealing with defense, aerospace, medical, and industrial systems, protecting sensitive design data and intellectual property is as critical as delivering flawless hardware.

Whether you’re a Federal Systems Integrator, a contractor in defense and space manufacturing, or an R&D partner driving technological breakthroughs, San Francisco Circuits’ PCB manufacturing and assembly solutions are tailored to meet the most demanding requirements and uncompromising cybersecurity.

Since 2005, San Francisco Circuits has been a trusted U.S. provider of advanced PCB manufacturing and assembly solutions for R&D innovators, prime contractors, and integration experts.

For federal and defense projects, reliability is paramount. San Francisco Circuits adheres to stringent standards and guidelines, including NIST 800-171 cybersecurity guidelines and ITAR compliance, ensuring that your mission-critical systems meet or exceed all regulatory requirements.

Through a network of rigorously qualified domestic partners, SFC delivers precision, rapid prototyping, and mission-critical reliability — all while maintaining the highest standards of data protection and supply chain security.

SFC understands that system integrators often operate within high-security environments, handling Controlled Unclassified Information (CUI) and ITAR-regulated data. To protect this information, SFC has implemented a comprehensive cybersecurity framework aligned with NIST SP 800-171 and CMMC (Cybersecurity Maturity Model Certification) requirements.

Key cybersecurity measures include:

These controls allow SFC to maintain trusted relationships with defense and aerospace primes, ensuring confidentiality, integrity, and traceability at every stage of the PCB lifecycle.

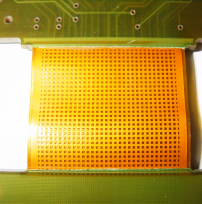

Six main pillars of a successful cybersecurity program, providing a foundation for meeting NIST 800-171 requirements

Image Credit: National Institute of Standards and Technology (nist.gov) N. Hanacek/NIST

SFC’s technical depth spans rigid, flex, and rigid-flex PCB fabrication, with a focus on high-density interconnect (HDI) and RF/microwave designs required by integrators in advanced systems. Our Design for Manufacturing (DFM) support and end-to-end quality management (ISO 9001:2015 certified) provide integrators with the assurance of both engineering accuracy and process control.

We have a strict adherence to IPC 6012 Class III standards in most fabrication and assembly applications. As needed, we also adhere to other advanced IPC guidelines and quality assurance standards such as:

We also follow certifications and QA processes with:

Innovation thrives on speed. Our rapid PCB prototyping services empower R&D teams to test and iterate quickly, ensuring faster time-to-market for groundbreaking technologies. We specialize in custom designs and small-batch runs, ideal for research and development.

Bare Board Fabrication or Assembly (up to 6 layers)

Fabrication & Assembly (up to 6 layers)

Standard Prototype (up to 16 layers)

High-Layer PCB Prototype (16 - 40 layers)

Benefits for system integrators include:

We can turn your rigid flex PCBs in 7 days with .006" min hole size & .003" min. trace/space.

San Francisco Circuits serves industries where performance and security converge:

For system integrators, every connection matters — and that includes the partner you trust with your intellectual property and system backbone.

With San Francisco Circuits, you gain more than a supplier — you gain a cyber-secure manufacturing ally who delivers precision-engineered PCBs backed by industry-leading data protection and mission-level reliability.

When performance, quality, and cybersecurity are non-negotiable, San Francisco Circuits is the partner that delivers.