Bring your concept to reality with San Francisco Circuits—your dedicated partner for flex PCB manufacturing and assembly.

We specialize in getting reliable flexible PCBs built - fast. Whether your application demands a double-sided flex board or a complex multi-layer one, we have you covered.

Our clients select us as their flex PCB vendor for our ability to reliably provide the most advanced technologies at fast turn times. With San Francisco Circuits’ engineering and support team you can expect unparalleled quality for your next prototype or production PCB run.

We can turn your flexible PCB manufacturing order in as little as 72 hours.

Bareboard Flex Fabrication

Fab + Assembly

(full + partial turnkey)

Call us at 800.SFC.5143 or get an instant PCB quote.

| Specifications | Capabilities |

|---|---|

| Drill to copper – Outer layers | 8 mil |

| Drill to copper – Inner layers | 10 mil |

| Copper Thickness | 0.5 oz - 4 oz |

| Minimum Hole Size | 0.003" |

| Minimum Trace/Space | 0.003"/0.003" |

| Minimum Pitch | 0.5 mm |

| Copper to board edge | 0.007" |

| Coverlay Opening | 0.004" |

| Coverlay Web (Kapton) | 0.006" |

A flex PCB is a patterned arrangement of printed circuitry and components built on a flexible base material, typically polyimide, that allows the board to conform to a desired shape (flex - bend, fold, twist) to fit its intended application.

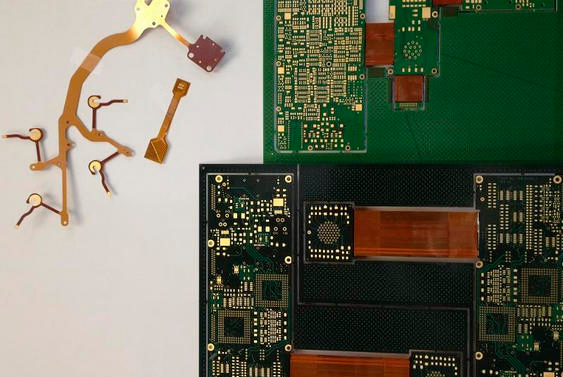

Flex PCBs can be manufactured with or without a flexible coverlay and may use the same components used on traditional rigid PCBs. By eliminating the need for bulky wiring harnesses and ribbon connectors, flex PCBs reduce weight, save space, and improve overall durability.

Depending on the design complexity, a flex PCB can range from a simple copper-polymer construction to a multi-layered build incorporating adhesives and advanced materials.

Flexible Circuit Boards

Photo Credits: Robert Tarzwell

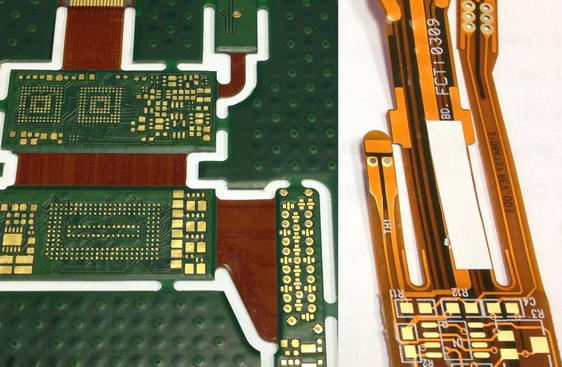

Like rigid PCBs, flex PCBs can be single-sided or double-sided. They can also be multi-layered, which is often common especially in high-speed and high-density applications, where advanced performance and space optimization are critical.

Flexible boards offer greater design versatility compared to traditional rigid FR4 boards, enabling more complex and compact layouts. Similar to multi-layer FR4 designs, multi-layer flex circuits can incorporate blind and buried vias, as well as plated through-holes (PTH), to support intricate interconnections across layers.

IPC 6013 Type 1 - Single-Sided Flex PCB

IPC 6013 Type 2 - Double-Sided Flex PCB

IPC 6013 Type 3 - Multilayer Flex PCB

IPC 6013 Type 4 - Rigid-Flex PCB

With offices in San Mateo and San Diego, California, San Francisco Circuits has been providing advanced flex printed circuit board fabrication, assembly, and services worldwide since 2005.

Since our company's founding, we have built up a reputation of reliably delivering innovative circuit solutions.

Thin polyimide substrates are used to compose flex boards (the thinnest being 12.5 microns and the most commonly used thin application being 25 microns). These substrates offer excellent bendability, flexibility, and tensile strength, allowing the circuits to conform to tight spaces and curved surfaces. Their lightweight nature also makes them ideal for applications where weight reduction is critical.

Unlike rigid FR4 boards, flex PCBs eliminate the need for traditional wiring harnesses and ribbon connectors, streamlining design and improving durability.

Single-sided and double-sided flex boards are composed of just two main layers: copper and a polymer film. In more complex builds, adhesives may be added between layers. Unlike rigid polyimide materials, which often include glass reinforcement, flexible polyimide substrates are free of such fillers to maintain maximum flexibility.

Polyimide is the most commonly used base material in flex PCB construction due to its high heat resistance, durability, and flexibility. DuPont® offers several notable polyimide product lines for flexible circuit applications, categorized by material composition and performance characteristics. These are typically available in adhesive and adhesive-less forms.

DuPont® Pyralux® LF

LF are acrylic-based laminates designed for basic jobs and products not requiring a UL safety rating. They can be purchased with the adhesive, without it, or combined with adhesive and copper on either side. Unfortunately, LF is not UL-approved due to its lower resistance to heat and intense temperatures.

DuPont® Pyralux® FR

Pyralux FR is also acrylic-based and is designed to be fire retardant, making it UL-rated. There is FR adhesive as well as FR dielectric.

DuPont® Pyralux® AP

Pyralux AP is an all-polyimide design with double-sided copper. While there are other high-speed, durable, and ultra-thin materials like TK, they require specialized processing. There is another adhesive-less material from DuPont® called AC, which features 1 side of copper whereas flex boards typically have 2 copper layers or more.

Flex Material Selection Considerations

The primary differences between these materials relate to:

Standard polyimide materials exhibit a higher glass transition temperature (Tg) of approximately 260°C, compared to 170°–180°C for high-temperature FR4. Polyimide can also absorb up to 20 times more moisture than FR4, a factor to consider in high-humidity environments or where dimensional stability is critical.

Read more in our PCB material reference guide.

Compared to rigid PCBs and traditional cable assemblies, flexible PCBs offer a wide range of advantages, particularly in compact, high-performance, or dynamic environments.

Compared to rigid PCBs and traditional cable assemblies, flexible PCBs offer a wide range of advantages, particularly in compact, high-performance, or dynamic environments.

Flexible PCBs are used across a wide spectrum of industries—from everyday consumer devices to high-performance, mission-critical applications. Some of the most prominent examples of flexible circuits can be found in modern portable electronics, devices, hard disk drives, and desktop printers.

Common applications include:

Flexible circuits are favored in transportation and other harsh environments thanks to their ability to absorb movement and vibrations, reduce mechanical failures, and maintain performance under physical stress.

Heavy copper flex circuit boards are engineered to handle higher power currents while maintaining flexibility. These boards combine thick copper layers with flexible base materials, making them ideal for high-current applications.

They can also be integrated with lower-voltage flex sections to create hybrid designs, offering both power and signal capabilities within a single circuit.

Read more about heavy copper PCBs.

Because of a strong network with the best flex PCB manufacturers, San Francisco Circuits can provide our customers with flex printed circuit boards with a great variety of technologies, from simple single-sided flex boards to complex multilayer flex, from commercial applications to high reliability military PCB. We can turn your flex PCBs as fast as in 72 hours, depending on technologies. If you’re looking for production quantities of flex or a flex pcb prototype, SFC’s experts are there to assist with every step of the process at the best value.

Call us at 800.SFC.5143 or get an instant PCB quote. Tell our experts what you need and we will provide you with the right production and assembly solution. Let our flex experts guide your project from concept to completion—on time and within budget.